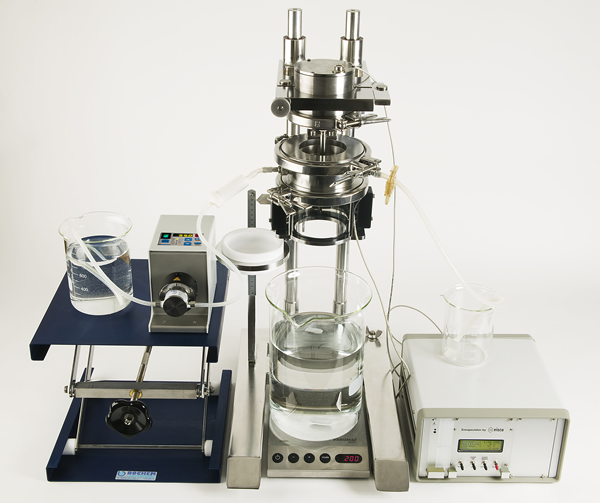

Open electromagnetically driven multi nozzle unit

Legend:

1 Feed vessel

2 Feed pump

3 Control cabinet

4 Vibrator

5 Pulsation chamber with membrane

6 Connection for vent

| 7 Nozzle plate

8 Sightglass with stroboscopic light

9 Bypass system

10 Vessel with hardening solution

11 Hardening solution with beads

12 Laboratory stirrer |

| Pos. 2-9 are included in our basic package; other positions are optional. |

Short description

This is an electromagnetic driven single nozzle unit based on the laminar-jet-breakup. The open version of the encapsulation system is specially suitable for the determination of the physical parameters during the scaling-up (e.g. flow rate, vibration frequency and amplitude) or for non sterile encapsulation processes. An open unit ensures you fast access to the beads, minimising time required for the optimisation of the parameters.

Applications

For a large number of applications (e.g. enzyme or drug immobilisation, cell encapsulaiton, cosmetic applications and many more) microencapsulation opens new technological possibilities.

Principle

A non sterile pump is used to generate a steady pulsation-free flow to the vibrating chamber. The bead generating unit has 13 nozzles. The vibration is superimposed on the product feed in the vibrating chamber by means of a membrane (frequency and amplitude can be adjusted digitally). The generated drops can be observed by means of an LED-stroboscopic light as stationary chains of parallel drops. The stroboscopic light is automatically synchronised with the adjusted vibration frequency. Monodisperse beads of the size between 0.2 and 1.5mm can be generated. The deviation between the applications mainly depend on the viscosity and the surface tension of the matrix. You can roughly estimate that the smallest achievable drop diameter is 1.5 to 2 times larger than the used nozzle diameter. The average productivity per nozzle is 400ml per hour whereas it can significantly differ in function of the nozzle diameter and the jet speed.

Control cabinet

Rack with display, four lines x 16 characters, programmable micro controller for vibration control and stroboscopic light.

Power supply between 110 V and 240 Volt, automatic adjusting.

Picture: Open 13 nozzles system with peristaltic pump

Picture: Open 13 nozzles system with gear pump

PDF Download:

http://www.equl.com/downloads/products/nisco/Encapsulation1.pdf

http://www.equl.com/downloads/products/nisco/Encapsulation1.pdf

http://www.equl.com/downloads/products/nisco/Encapsulation3.pdf

Encapsulation System Publications

Papers for Download